Treatment Types

Many types of pavement treatment options are available for the streets and many factors are considered in selecting the right treatment for each street, including the type and severity of the pavement distresses as well as the PCI values.The PCI, an index ranging from 0 to 100, is an indicator of the health of the overall pavement network. The higher the PCI value, the better the road condition is. A PCI of 0 indicates a failed pavement and a PCI of 100 indicates a new pavement with no distresses. A PCI of 80 suggests the pavement is in "State of Good Repair".

The City's current PCI is 62, with 30% of pavement lane miles in 'Poor' condition suggesting there should be improvements to the pavement.

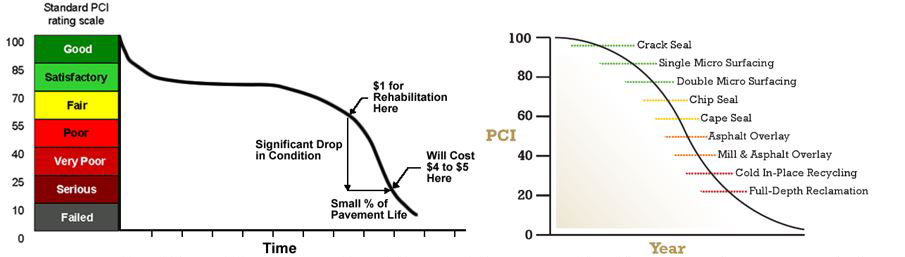

Preservation consists of work that is planned and performed to improve or sustain the condition of the transportation facility in a state of good repair. Under most circumstances, the condition of a pavement over time can be represented by a curve similar to the one shown below. The worse the pavement condition is, the more expensive treatment is required to restore the pavement to good condition. A relatively inexpensive pavement preservation treatment earlier in the pavement's life cycle, while it may only bring a slight improvement in the condition of the pavement, still makes a tremendous difference when considering that it postpones or avoids the need for a much more expensive treatment later on.

Pavement treatments that consist of structural enhancements that extend the serviceable life of an existing pavement and improve its load-carrying capability. Rehabilitation consists of improvements made to an existing pavement section that has progressed beyond the effectiveness of functional improvements achieved by pavement preservation treatments. Typical treatments include mill and overlay, resurfacing with full depth reclamation, cold-in-place recycling, and hot-in-place recycling.

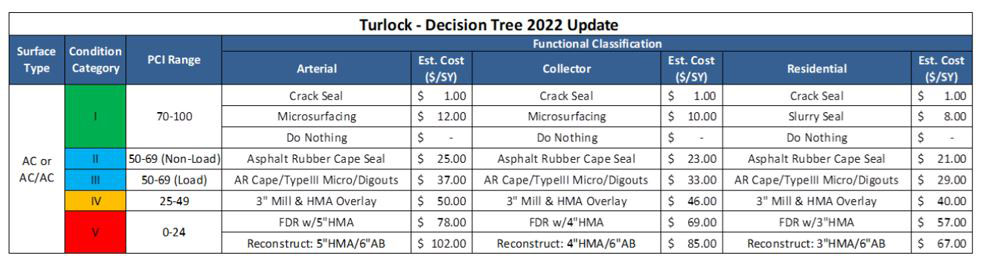

A Decision Tree was developed to help determine the suggested treatment types and associated costs based on pavement condition. There are several options for pavement rehabilitation, and not all are listed in the Decision Tree.

Pavement Treatment Types

Crack Sealing

Crack Sealing involves placement of an adhesive material into working cracks at the pavement surface in order to prevent the infiltration of moisture into the pavement structure. Crack/joint sealing is effective at reducing or delaying moisture damage due to infiltration of water into the cracks, further crack deterioration, roughness, and rutting.

Fog Seal

A fog seal is a light application of a diluted slow-setting asphalt emulsion to the surface of an aged pavement surface. Fog seals are low-cost and are used to restore surface appearance of an existing asphalt pavement surface, seal minor cracks, prevent water penetration, and inhibit raveling.Slurry Seal

Slurry Seal is a mixture of polymer modified asphalt emulsion, well-graded high-quality aggregate, mineral filler, water, and other additives, properly proportioned, mixed, and spread on a paved surface. It is used to fill minor cracks and seal areas of aged pavements, to restore a uniform surface texture, to seal the surface to prevent moisture and air intrusion into the pavement, and to improve skid resistance. Slurry seal can be used as a final riding surface or as an intermediate layer prior to a final overlay treatment.

Microsurfacing

Microsurfacing is a mixture of polymer modified asphalt emulsion, well-graded high-quality aggregate, mineral filler, water, and other additives, properly proportioned, mixed, and spread on a paved surface. Microsurfacing differs from slurry seal in that it can be used on higher volume roadways to correct wheel path rutting and provide a skid resistant pavement surface. Microsurfacing can be used as a final riding surface or as an intermediate layer prior to a final overlay treatment. Microsurfacing is 25 – 40% of the cost to grind and overlay treatments with expected pavement life extension of 5 – 10 years.

Cape Seal

A cape seal is a combination of a chip seal followed by a slurry seal or a microsurfacing. Cape seal provides the benefits of both the chip seal and the slurry seal or micro surfacing treatment, namely sealing moderate cracks, providing skid resistance, sealing the pavement against moisture intrusion, protecting the structure from further oxidation and raveling, and restoring a uniform black appearance

Asphalt Rubberized (AR) Cape Seal

Conventional cape seals are not recommended for pavements with structural deficiencies/load related distresses such as alligator cracking. However, roads that have alligator cracks measuring 3/8" to 1/2" can be sealed with AR Cape Seals. In an AR Cape Seal, hot, viscous, asphalt-rubber binder is applied to the road. Then preheated aggregate chips are dropped into the binder. The chips are rolled into the binder with pneumatic rubber-tired rollers. Then any excess chips get swept up and disposed of. A Type II slurry seal is then applied on top as a cape. The Type II slurry seal fills in all the roughness in the AR Chip Seal, making it more "neighborhood friendly" for residents to recreate with their skateboards, rollerblades, and scooters making it ideal for residential street applications.

Asphalt Concrete Overlay (Most Commonly HMA Overlay)

Asphalt Concrete (AC) consists of mineral aggregate bound together with asphalt, laid in layers, and compacted. The most common AC type used on streets and highways is Hot Mix Asphalt (HMA).HMA overlay is the most common road maintenance and restoration treatment and has been used for many decades. It produces durable, smooth, and skid resistant surface for motorists and can increase the pavement life by 15 years or more. Combined with other processes, such as milling or grinding old pavement, an HMA overlay can transform a tattered road surface into a like-new condition.

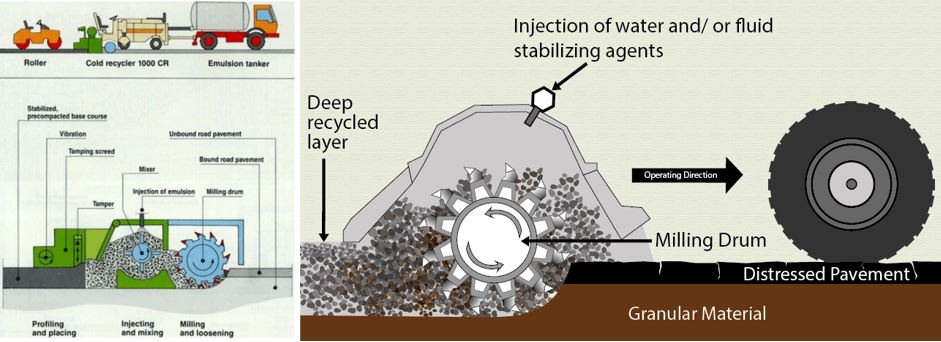

Cold-In-Place Recycling (CIR)

Cold-in-Place (CIR) recycling is a method of removing and reusing the existing asphalt surface. It involves grinding off the top 2 to 5 inches of the existing asphalt surface, mixing the milled asphalt with an asphalt recycling agent, and placing it back down with a paver.Full-Depth Reclamation (FDR)

Full-Depth Reclamation is a type of complete road reconstruction or reconstruction technique where the old, deteriorated asphalt pavement along with a predetermined portion of the base, and/or subbase materials are pulverized, mixed, and treated with a stabilizing agent (such as cement or asphalt emulsion) to produce a like-new road base. Typically, the roadway is then re-surfaced with new HMA.Using in-place materials minimizes the need to haul in aggregate or haul out old material for disposal. Truck traffic is reduced, and there is little or no waste. Due to reduced transportation, FDR costs are far less than the conventional reconstruction and can provide up to 30 years of additional life.